Autonomous Industrial Patrol Ground Robotics System

Description

The system is a cyber-physical stack for autonomous patrolling of industrial sites using ground robots, combining global and local perception to enable reliable operation in dynamic environments. The main computing unit is a compact industrial PC with multiple Ethernet interfaces, enabling separation of sensing subsystems into independent networks and supporting high-bandwidth data streaming. Navigation and obstacle perception are based on multiple 3D ranging sensors, complemented by a multi-constellation satellite-based positioning system with redundant antennas for robust and accurate localization. Vision sensors provide high-resolution visual data for object detection and classification, while a cellular communication module ensures low-latency, high-throughput connectivity with the control center for real-time data and video transmission.

Patrol Stack for Ground Robots

A stack for autonomous patrol of an industrial site using ground robots is a cyber-physical system that combines global and local perception of the environment to ensure autonomous operation of robots in a dynamic environment.

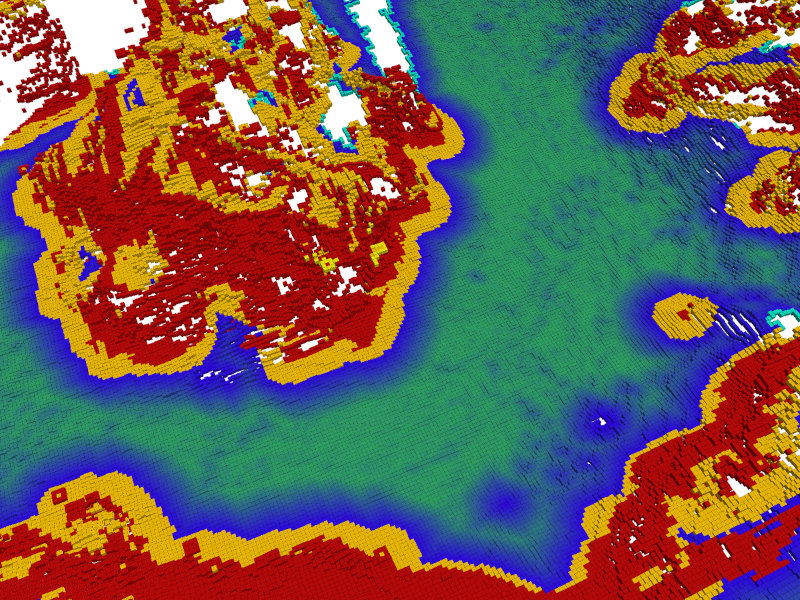

The deployment of the system can be divided into two phases: a preparatory phase and an operational phase. In the preparatory phase, the system is used to create a map of the site with annotated traversability. Based on this map, inspection routes are then generated automatically. In the operational phase, these routes are used for autonomous navigation of the robots within the site, while the robot continuously updates a local 3D model based on sensor data and adapts its route to the current conditions in the environment.

Preparatory Phase: Offline Patrol Preparation

Preparation of the Floor Plan Map of the Inspection Area

In the preparatory phase, a **3D point cloud** of the inspection area is first created, for example using a LiDAR sensor mounted on a ground robot or a total station. The point cloud is projected onto a **floor plan map**, where an operator manually annotates the areas in which the robot is allowed to move and where it is required to perform inspection.